Wood-based panels

Innovative evaporation plants from SCHRADER

Innovative evaporation plants from SCHRADER reduce the amount of wastewater in the production of wood-based panels (MDF, HDF) by 100% and reduce fresh water requirements by 50%.

Both the steam produced and the energy generated by the downstream incineration of the separated solids are fed back into the process, thus reducing production costs. SCHRADER develops turnkey plants tailored to customer requirements, thus ensuring optimal and sustainable production conditions.

Cost savings through wastewater treatment

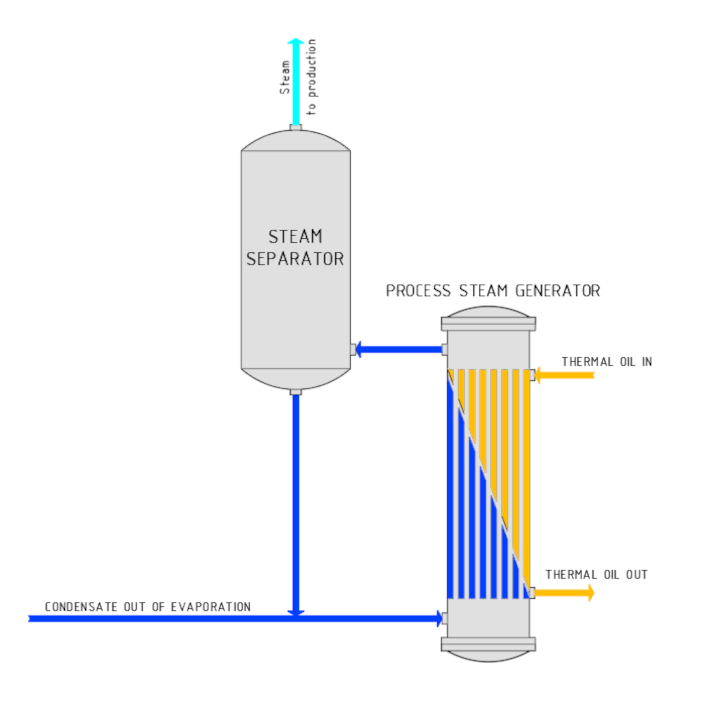

The manufacture of MDF and HDF boards, in particular, produces wastewater that is contaminated with process-specific residues and which cannot be discharged via municipal wastewater management facilities. With solutions from SCHRADER, wastewater treatment in the manufacture of wood-based panels produces no residues, as the separated solids are incinerated. In the process steam generator, the condensate is converted into process steam by the addition of thermal energy before being fed back into the refiner. This allows you to meet the requirements set by the authorities, save on wastewater charges and ensure your production process is extremely energy-efficient.

SCHRADER Supervision

SCHRADER Supervision is a cloud-based system for the monitoring, storage and visualization of process and plant data for SCHRADER Evaporation and Steam Generation plants

Use in process steam generation

Energy generation

Return to the manufacturing process

Reduction in wastewater

Incineration of the separated solids and concentrate

Indirect energy generation and waste avoidance

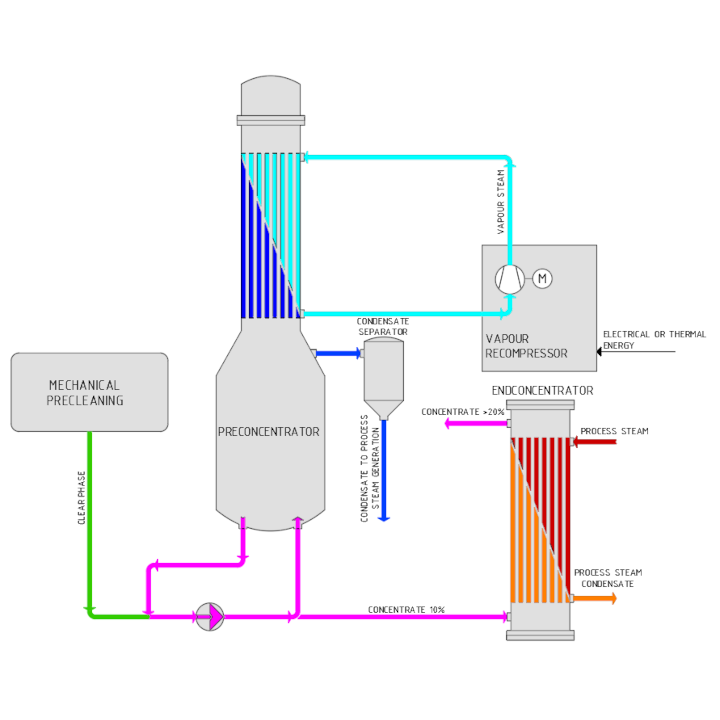

MVR-TVR heated wastewater treatment plant

SCHRADER designs complex evaporation plants that are precisely tailored to your requirements. The plants are scaled on the basis of feed parameters such as volume, pressure and temperature – while ensuring that energy efficiency and plant safety are always the primary focus.

Mechanical vapour recompression

The vapours (steam) from the evaporation pre-concentrator are compressed by means of an electrically operated vapour compressor (fan) and thus brought to a higher energy level.

Thermal vapour recompression

The vapours (steam) from the evaporation pre-concentrator are brought to a higher energy level by the addition of heating steam.

You determine the degree of automation (from manual operation to fully automatic operation, as required).

- Consulting to determine the necessary equipment

- Process requirements

- Individual adjustments

- Options and possibilities: from the necessary to the convenient

The aim is an optimal interaction of all components, control instruments and measuring instruments under real production conditions. We also take care of the necessary documentation.

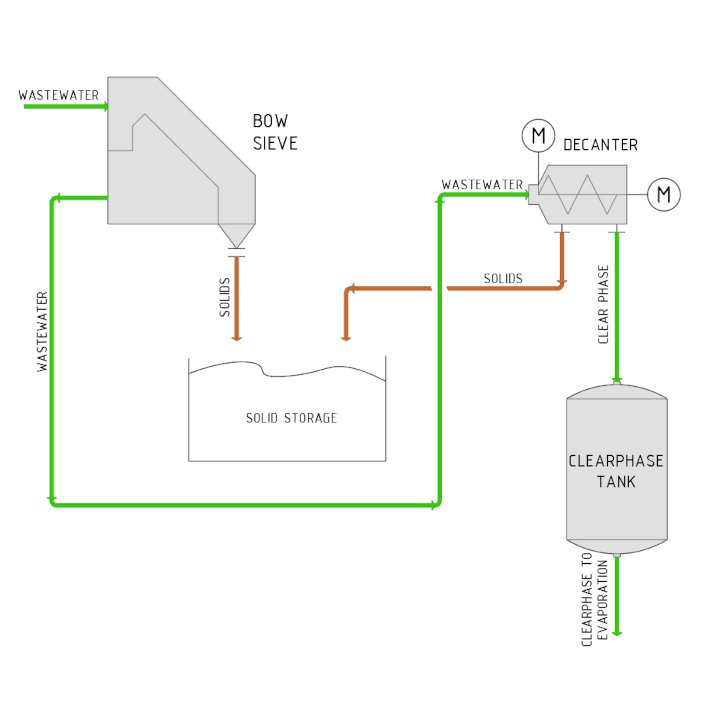

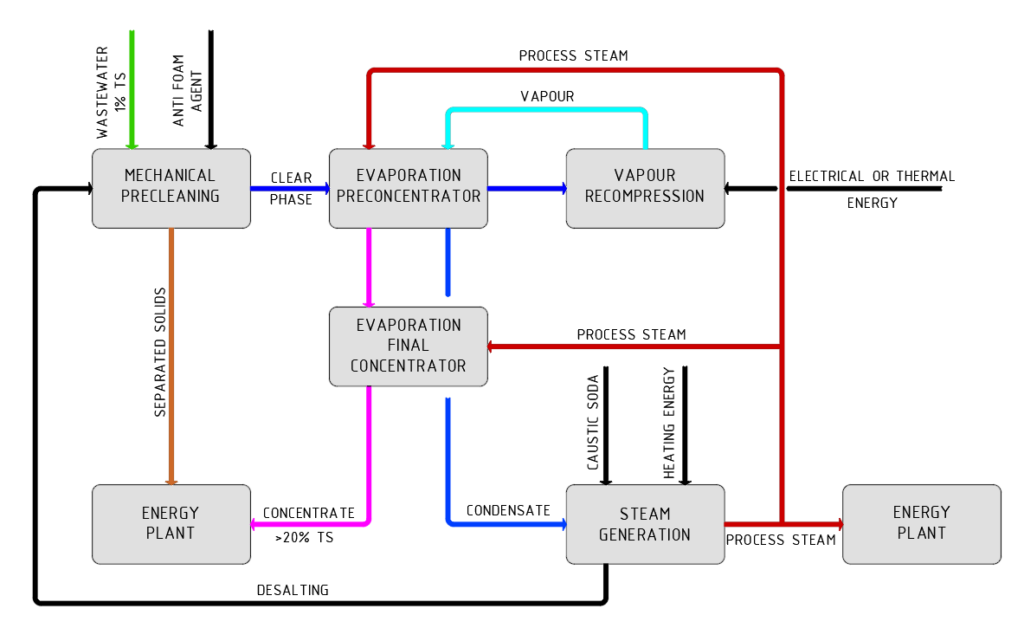

Process overview: wastewater evaporation

The treatment of process water for the production of wood based panel comprises the following sub-steps, which can be operated independent from the others and in different places of the plant.

Mechanical pre-treatment: separation of wood components > 1mm in the water

- Separation of particles > 3 mm from the process wastewater by means of a bow screen

- Fine separation of turbid materials > 1 mm by means of a decanter centrifuge

- Feeding of pre-cleaned wastewater to evaporation

- Feeding the solid material to incineration

Evaporation: Evaporation of water to produce condensate as Feedstock for process steam generation

- Concentrates wastewater to 10% dry substance without end concentrator or 30% dry substance with end concentrator

- Use of the vapour as a heating medium by means of mechanical vapour recompression (MVR)

- Feeding the concentrate to incineration

Turnkey solutions from SCHRADER: individual plants with standardised processes

Thanks to our many years of experience with individually optimised evaporation plants, we understand the performance targets for a wide range of projects. From mechanical pre-cleaning to evaporation and process steam generation, SCHRADER is a global market leader. We, therefore, ensure durability, efficiency and calculable plant costs.

Concept

Concept

pre-engineering

Engineering

Engineering

detail engineering

Implementation

Implementation

procurement,

assembly

Commissioning

Commissioning

documentation

Customer service

Customer service

spare parts,

service,

maintenance

The advantages of residue-free wastewater treatment at a glance

Effluent-free

Solids are incinerated and the steam generated from the process water is fed back into the process as energy.

Compliance with regulations

Requirements and conditions set by the authorities are fulfilled, as no wastewater is generated during the production of MDF and HDF panel boards.

Fully automated process with integrated CIP programme

No interruption of evaporation or process steam generation for cleaning purposes.

Energy efficient

Uses the condensation energy from the evaporation process to heat the evaporator.

Reduced freshwater consumption

50% reduction in freshwater, as boiler feed water.

Cost-saving

Avoidance of wastewater charges by reducing wastewater to “zero”.

98.9% plant availability

No significant interruptions in your production process.

Process is virtually maintenance-free

Stand-alone operation of the entire system.

Contact

Our global network of experienced engineers is available to you by phone or e-mail. Don’t hesitate to get in touch.